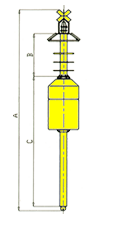

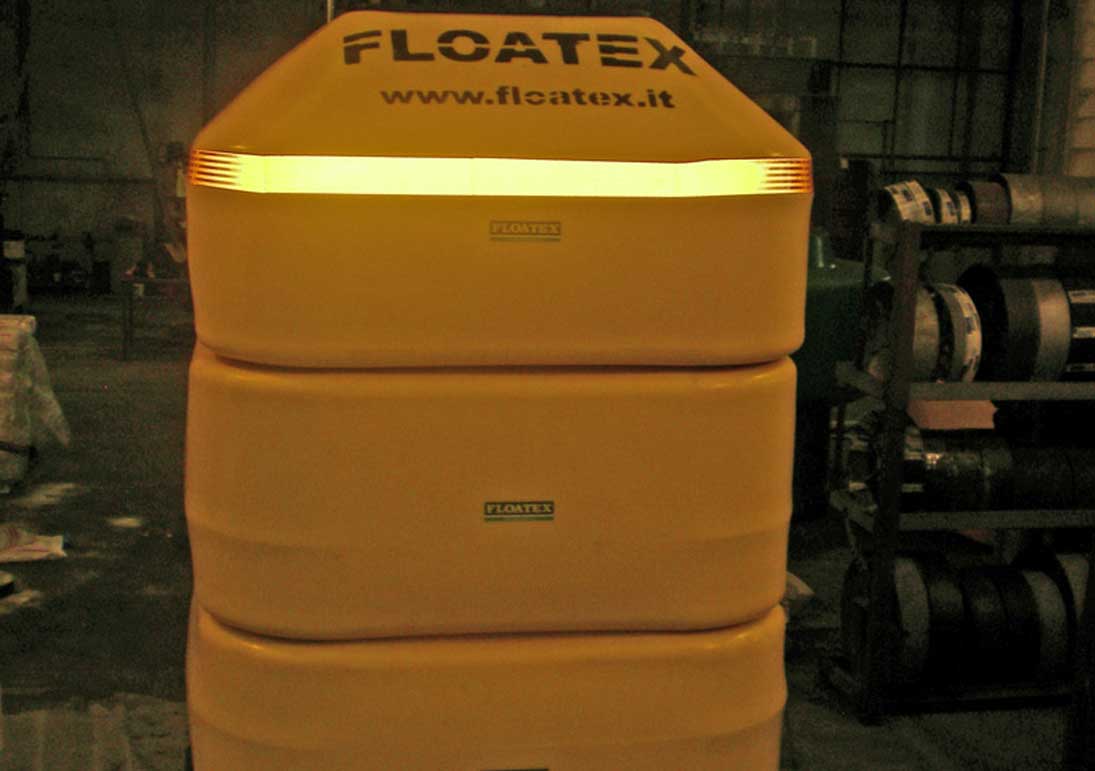

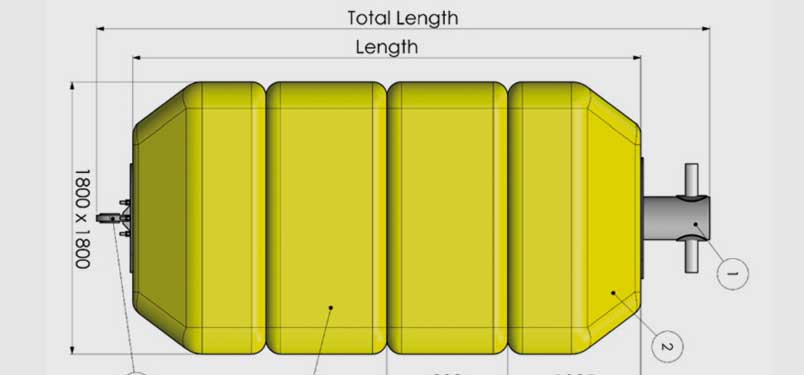

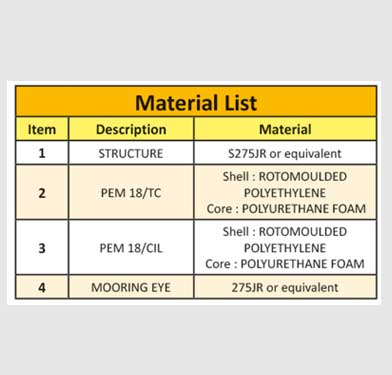

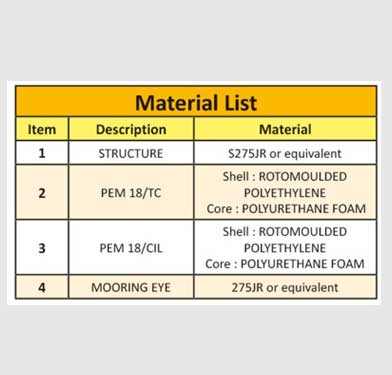

Floating module made in UV-stabilized linear virgin polyethylene. The Polyethylene used in the manufacturing process is completely recyclable (Eco-Friendly), it's fully compatible with the marine environment, and has a high resistance to UV rays. Being linear has the advantage that it can be melted and hence repaired by hot fusion welding. The colour pigment is moulded-in and consequently not added as a coating ensuring greater life of the color and a big help to the environment as it never requires additional paintings, avoiding toxic dispersions in the water. Floatex polyethylene require a minimal maintenance. R&D laboratory daily perform test on production samples such as tensile test, hardness test, abrasion test, UV test and Cold temperature test, colour test and other ordinary tests in the aim to ensure the quality and the reliability of Floatex polyethylene. Inner filling of the buoy: The module is filled with closed-cell able to resist to the hydrostatic pressure at OPERATING WATER DEPTH. The polyurethane foam ensure great resistance to the leakage of air or water, ensuring unsinkability to the buoy also in case of accidental breaks of the outer shell. The polyurethane foam is 100% made and tested before production by our R&D laboratory. Steel hardware: Central steel rod c/w locking plates at both end of the floating module. BOLLARD or PAD EYE at both ends to facilitate the operation of handling and the connection with the chain/rope. The metal parts are HOT DEEP GALVANISED.

FLOATEX SRL

Since 1976 FLOATEX pioneers the application of rotomoulded products and technology in the offshore fields